- Joined

- Sep 9, 2012

- Messages

- 608

- Location

- Wiedemar, Germany

- First name

- Joachim

Machinery:

Zetor 2011, Zetor 3045, Zetor 5011, Zetor 7340 Economic

Checking and interpreting compression

Preliminary summary:

Zetor itself wrote in a sales brochure for sales partners in 1986 that a 5211 to 7745 should have a compression of 25-28 bar.

In this respect, the conclusion from the following text is largely correct and confirmed.

Zetor UR1:

Maximum permissible deviation of compression between the cylinders of an engine: 3 bar

Our recommendation: maximum 2 bar deviation, better no deviation!

The theory for understanding:

The compression ratio E is therefore not the "correct" pressure that should be measured in a compression test, but simply the ratio between the volume of air taken in and the volume of compressed air (E = v1 / v2) under ideal conditions (complete sealing of the piston and no heat release of the compressed air to the environment). The compression ratio on the Zetor UR1 is usually specified as E = 17. The compression ratio can also be described as follows:

E = (vstroke + vpiston chamber) / vpiston chamber

vstroke = piston displacement between BDC and TDC

vpiston chamber = the volume that remains at TDC = v2

vstroke + vpiston chamber = v1

As already mentioned above (see "compression ratio"), the compression test to assess the compression of a cold diesel engine is an indication of the state of wear of the piston, piston rings and cylinder bore.

In order to be able to estimate this, you now have to know which compression ratio is actually assumed under ideal conditions (for the Zetor 50 Super it is 15.6, for the Zetor UR1 17 and so on and so forth). Then, after calculation in the ideal state and after compression testing with the engine cold, you can draw conclusions about the wear of the piston/piston rings/cylinder bore.

In the ideal state of the running diesel engine (E = 17; with isentropic exponent k of 1.4, without heat loss of the compressed air to the environment and complete tightness between piston and cylinder) the pressure after the compression stroke is:

p2 = p1 x E to the power of k = 1 bar x 17 to the power of 1.4 = 52.79 bar

In the real state of the running diesel engine (E = 17; with polytropic exponent k of 1.3 (i.e. with generous heat loss) and complete tightness between piston and cylinder) the pressure at the end of the compression stroke is:

P2 = p1 x E to the power of k = 1 bar x 17 to the power of 1.3 = 39.77 bar

Carrying out the compression test:

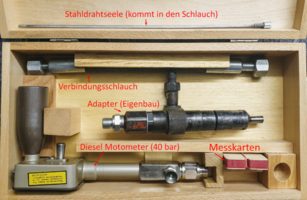

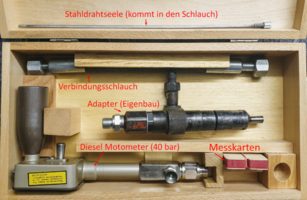

For this you need a compression tester for the diesel engine (manometer with a Measuring range of at least 30 bar, preferably 40 bar or a professional device such as a Diesel Motometer), which you can buy.

However, the Zetor UR1 does not have a thread to screw an adapter into the hole of a glow plug, but you have to use the "hole" in the cylinder head where the nozzle holder would otherwise be.

You have to "tinker" a bit, for example to fix a rubber cone with the yoke of the nozzle holder in the hole or to modify an old nozzle holder. Important: in order not to get falsely low values, the air volume outside the combustion chamber - i.e. in the adapter, the hose to the pressure gauge or motometer - must be kept as low as possible. In professional devices, for example, a steel wire core is pushed into the hoses to reduce the internal air volume to the absolute minimum.

Diesel Motometer: around 400 euros new, or 80-160 euros used

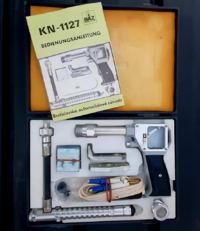

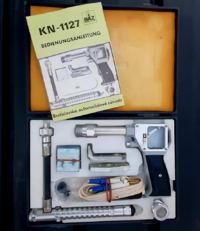

Diesel Motometer Czech version BAZ KN 1127, originaly made for Zetor tractors: around 200-300 euros used

It already has the perfect insert adapter for use in the nozzle sleeves instead of the nozzle holder and is extremely rare to find. I have a case like this in mint condition, so I could measure the insert adapter if necessary.

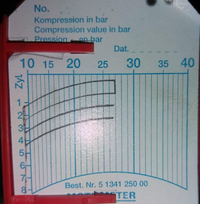

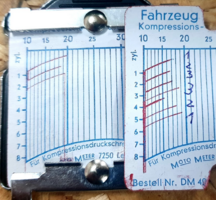

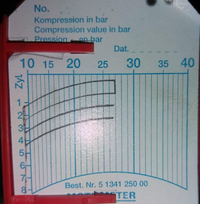

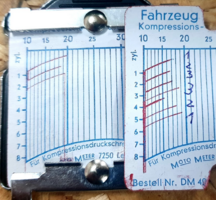

Motometer measurement sheet examples:

Very good, consistent values from a 4-cylinder Zetor diesel engine

Rather poor values, with strong deviations between the cylinders. Please note that too high an internal air volume in the adapter was also to blame for the low values - but not for the deviations between the cylinders.

Standard diesel pressure gauge for compression test: approx. 120 euros new

Preparatory work before you can measure:

Now operate the starter motor (approx. 5 seconds) until the pressure displayed no longer increases and then read the maximum pressure on this cylinder and note it down. Repeat the whole process for the rest of the engine's cylinders.

When you get the results for the entire cylinder bank (all cylinders), please don't be alarmed if it's "only" 21-23-22-24 bar.

Reasons for lower values than desired:

A little more theory:

In the formula p2 = p1 x E to the power of k, only the E changes during the compression test. p1 remains the same, k remains approximately the same, only the E has deteriorated during testing on the cold engine (high air leakage due to low piston speed and insufficient oil supply).

The compression ratio E during the compression test on a cold engine is therefore not the E for a warm engine and not the E for a completely "airtight" engine.

The actual measured compression ratio E on the cold engine therefore showed a maximum pressure of 25 bar at best. 25 bar on a cold engine is a very good value that can be measured during the compression test. This is no different with a brand new engine.

From the measured maximum pressure p2 of 25 bar when the engine is cold, one can in turn deduce the actual compression ratio when the engine is cold (E_cold):

E_cold = k root of (p2/p1) = 1.3 root of (25 bar / 1 bar) = 11.89

If the result of the compression test is only 20 bar for p2, the E_cold is:

E_cold = 1.3 root of (20 bar / 1 bar) = 10.01

If the result of the compression test is only 15 bar for p2, the E_cold is:

E_cold = 1.3 root of (15 bar / 1 bar) = 8.02

That's all well and good, some people may ask, but what can you do with this determined E_cold?

This allows you to determine the temperature of the air at the end of the compression stroke! Since the injected diesel only ignites at around 250°C or 523.15 Kelvin, you can use the determined E_cold to judge at what ambient temperature this tested diesel engine actually starts.

The only important thing now is that you have to think and calculate in Kelvin and not in °Celsius:

T2 = T1 x E_cold to the power of (k-1)

Formula symbol:

T2 = temperature of the air at the end of compression in Kelvin (0°C corresponds to 273.15 Kelvin)

T1 = temperature of the air at the start of compression in Kelvin (0°C corresponds to 273.15 Kelvin)

E_cold = result from the compression test in bar

k = polytropic exponent (1.3)

At 20°C (corresponds to 293.15 Kelvin) you get a compression ratio of E_cold = 11.89:

T2 = 293.15 x 11.89 to the power of (1.3-1) = 616.09 Kelvin, which corresponds to 616.09 - 273.15 Kelvin = 342.94 °C; The diesel engine will therefore ignite safely at 20°C.

At -20°C (corresponds to 253.15 Kelvin) with a compression ratio of E_cold = 11.89 you get:

T2 = 253.15 x 11.89 to the power of (1.3-1) = 532.02 Kelvin, which corresponds to 532.02 - 273.15 Kelvin = 258.87 °C; The injected diesel will therefore still ignite at an ambient temperature of -20°C and the determined E_cold of 11.89 degrees.

If you can now only determine 20 bar for E_cold in the compression test, things look correspondingly worse:

At 0°C (corresponds to 273.15 Kelvin) with a compression ratio of E_cold = 10.01 you get:

T2 = 273.15 x 10.01 to the power of (1.3-1) = 545.16 Kelvin, which corresponds to 545.16 - 273.15 Kelvin = 272.01 °C; The injected diesel will therefore still ignite at an ambient temperature of 0°C and the determined E_cold of 10.01. In order for this diesel engine to start safely even at temperatures below 0°C, you will probably have to resort to aids such as start pilot.

If you can now only determine 15 bar for E_cold in the compression test, it will probably be even worse:

At 0°C (corresponds to 273.15 Kelvin) you get a compression ratio of E_cold = 8.02:

T2 = 273.15 x 8.02 to the power of (1.3-1) = 510.09 Kelvin, which corresponds to 510.09 - 273.15 Kelvin = 236.94°C; The injected diesel therefore no longer really ignites at an ambient temperature of 0°C, the ignition temperature of injected diesel is not reached.

The interpretation of the measured compression pressures in conjunction with the achievable temperature / ignition temperature of the injected diesel is now sufficient. Deviating from the example calculations, everyone is of course free to enter, calculate and assess the values according to their tractor

Important: in order to assess where the problem lies if the compression is not as desired, you should do a pressure loss test with each cylinder. This usually shows clearly for each cylinder when - where the leak is. This allows you to repair it in a targeted manner.

The conclusion:

... but with an ideal compression ratio of 17:1 it does not look any better than before:

measured 25 -28 bar: very good

measured 20 -24 bar: OK, usable

measured 16 -19 bar: no longer good

measured 15 bar and less: bad - does not start at all or hardly at all when it gets cold

Preliminary summary:

Zetor itself wrote in a sales brochure for sales partners in 1986 that a 5211 to 7745 should have a compression of 25-28 bar.

In this respect, the conclusion from the following text is largely correct and confirmed.

- measured 25 -28 bar: very good

- measured 20 -24 bar: OK, usable

- measured 16 -19 bar: no longer good

- measured 15 bar and less: bad - does not start at all or hardly at all when it gets cold

Zetor UR1:

Maximum permissible deviation of compression between the cylinders of an engine: 3 bar

Our recommendation: maximum 2 bar deviation, better no deviation!

The theory for understanding:

The compression ratio E is therefore not the "correct" pressure that should be measured in a compression test, but simply the ratio between the volume of air taken in and the volume of compressed air (E = v1 / v2) under ideal conditions (complete sealing of the piston and no heat release of the compressed air to the environment). The compression ratio on the Zetor UR1 is usually specified as E = 17. The compression ratio can also be described as follows:

E = (vstroke + vpiston chamber) / vpiston chamber

vstroke = piston displacement between BDC and TDC

vpiston chamber = the volume that remains at TDC = v2

vstroke + vpiston chamber = v1

As already mentioned above (see "compression ratio"), the compression test to assess the compression of a cold diesel engine is an indication of the state of wear of the piston, piston rings and cylinder bore.

In order to be able to estimate this, you now have to know which compression ratio is actually assumed under ideal conditions (for the Zetor 50 Super it is 15.6, for the Zetor UR1 17 and so on and so forth). Then, after calculation in the ideal state and after compression testing with the engine cold, you can draw conclusions about the wear of the piston/piston rings/cylinder bore.

In the ideal state of the running diesel engine (E = 17; with isentropic exponent k of 1.4, without heat loss of the compressed air to the environment and complete tightness between piston and cylinder) the pressure after the compression stroke is:

p2 = p1 x E to the power of k = 1 bar x 17 to the power of 1.4 = 52.79 bar

In the real state of the running diesel engine (E = 17; with polytropic exponent k of 1.3 (i.e. with generous heat loss) and complete tightness between piston and cylinder) the pressure at the end of the compression stroke is:

P2 = p1 x E to the power of k = 1 bar x 17 to the power of 1.3 = 39.77 bar

Carrying out the compression test:

For this you need a compression tester for the diesel engine (manometer with a Measuring range of at least 30 bar, preferably 40 bar or a professional device such as a Diesel Motometer), which you can buy.

However, the Zetor UR1 does not have a thread to screw an adapter into the hole of a glow plug, but you have to use the "hole" in the cylinder head where the nozzle holder would otherwise be.

You have to "tinker" a bit, for example to fix a rubber cone with the yoke of the nozzle holder in the hole or to modify an old nozzle holder. Important: in order not to get falsely low values, the air volume outside the combustion chamber - i.e. in the adapter, the hose to the pressure gauge or motometer - must be kept as low as possible. In professional devices, for example, a steel wire core is pushed into the hoses to reduce the internal air volume to the absolute minimum.

Diesel Motometer: around 400 euros new, or 80-160 euros used

Diesel Motometer Czech version BAZ KN 1127, originaly made for Zetor tractors: around 200-300 euros used

It already has the perfect insert adapter for use in the nozzle sleeves instead of the nozzle holder and is extremely rare to find. I have a case like this in mint condition, so I could measure the insert adapter if necessary.

Motometer measurement sheet examples:

Very good, consistent values from a 4-cylinder Zetor diesel engine

Rather poor values, with strong deviations between the cylinders. Please note that too high an internal air volume in the adapter was also to blame for the low values - but not for the deviations between the cylinders.

Standard diesel pressure gauge for compression test: approx. 120 euros new

Preparatory work before you can measure:

- If possible, run the engine once more to warm it up a bit and lubricate the cylinder liners

- remove all nozzles

- Attach the compression tester or motometer (measuring range 40 bar) to the cylinder to be tested so that it is airtight

- Hand throttle to off so that no fuel drips out of the injection lines during testing.

- Battery should be fully charged so that no falsified results are caused by a starting speed that is too low.

Now operate the starter motor (approx. 5 seconds) until the pressure displayed no longer increases and then read the maximum pressure on this cylinder and note it down. Repeat the whole process for the rest of the engine's cylinders.

When you get the results for the entire cylinder bank (all cylinders), please don't be alarmed if it's "only" 21-23-22-24 bar.

Reasons for lower values than desired:

- Engine cold

- Starting speed too low (gearbox starters are an advantage as they usually have higher starting speeds)

- Leaks in the measuring device

- Excessive internal air volume on the measuring device, supply hose and/or adapter

- Leaks in the intake and/or exhaust valves

- Leaking piston rings/liners

- Uncalibrated measuring device

- New engine - new engines have up to 7 bar lower compression than engines after the running-in phase after at least 200 hours of operation!

A little more theory:

In the formula p2 = p1 x E to the power of k, only the E changes during the compression test. p1 remains the same, k remains approximately the same, only the E has deteriorated during testing on the cold engine (high air leakage due to low piston speed and insufficient oil supply).

The compression ratio E during the compression test on a cold engine is therefore not the E for a warm engine and not the E for a completely "airtight" engine.

The actual measured compression ratio E on the cold engine therefore showed a maximum pressure of 25 bar at best. 25 bar on a cold engine is a very good value that can be measured during the compression test. This is no different with a brand new engine.

From the measured maximum pressure p2 of 25 bar when the engine is cold, one can in turn deduce the actual compression ratio when the engine is cold (E_cold):

E_cold = k root of (p2/p1) = 1.3 root of (25 bar / 1 bar) = 11.89

If the result of the compression test is only 20 bar for p2, the E_cold is:

E_cold = 1.3 root of (20 bar / 1 bar) = 10.01

If the result of the compression test is only 15 bar for p2, the E_cold is:

E_cold = 1.3 root of (15 bar / 1 bar) = 8.02

That's all well and good, some people may ask, but what can you do with this determined E_cold?

This allows you to determine the temperature of the air at the end of the compression stroke! Since the injected diesel only ignites at around 250°C or 523.15 Kelvin, you can use the determined E_cold to judge at what ambient temperature this tested diesel engine actually starts.

The only important thing now is that you have to think and calculate in Kelvin and not in °Celsius:

T2 = T1 x E_cold to the power of (k-1)

Formula symbol:

T2 = temperature of the air at the end of compression in Kelvin (0°C corresponds to 273.15 Kelvin)

T1 = temperature of the air at the start of compression in Kelvin (0°C corresponds to 273.15 Kelvin)

E_cold = result from the compression test in bar

k = polytropic exponent (1.3)

At 20°C (corresponds to 293.15 Kelvin) you get a compression ratio of E_cold = 11.89:

T2 = 293.15 x 11.89 to the power of (1.3-1) = 616.09 Kelvin, which corresponds to 616.09 - 273.15 Kelvin = 342.94 °C; The diesel engine will therefore ignite safely at 20°C.

At -20°C (corresponds to 253.15 Kelvin) with a compression ratio of E_cold = 11.89 you get:

T2 = 253.15 x 11.89 to the power of (1.3-1) = 532.02 Kelvin, which corresponds to 532.02 - 273.15 Kelvin = 258.87 °C; The injected diesel will therefore still ignite at an ambient temperature of -20°C and the determined E_cold of 11.89 degrees.

If you can now only determine 20 bar for E_cold in the compression test, things look correspondingly worse:

At 0°C (corresponds to 273.15 Kelvin) with a compression ratio of E_cold = 10.01 you get:

T2 = 273.15 x 10.01 to the power of (1.3-1) = 545.16 Kelvin, which corresponds to 545.16 - 273.15 Kelvin = 272.01 °C; The injected diesel will therefore still ignite at an ambient temperature of 0°C and the determined E_cold of 10.01. In order for this diesel engine to start safely even at temperatures below 0°C, you will probably have to resort to aids such as start pilot.

If you can now only determine 15 bar for E_cold in the compression test, it will probably be even worse:

At 0°C (corresponds to 273.15 Kelvin) you get a compression ratio of E_cold = 8.02:

T2 = 273.15 x 8.02 to the power of (1.3-1) = 510.09 Kelvin, which corresponds to 510.09 - 273.15 Kelvin = 236.94°C; The injected diesel therefore no longer really ignites at an ambient temperature of 0°C, the ignition temperature of injected diesel is not reached.

The interpretation of the measured compression pressures in conjunction with the achievable temperature / ignition temperature of the injected diesel is now sufficient. Deviating from the example calculations, everyone is of course free to enter, calculate and assess the values according to their tractor

Important: in order to assess where the problem lies if the compression is not as desired, you should do a pressure loss test with each cylinder. This usually shows clearly for each cylinder when - where the leak is. This allows you to repair it in a targeted manner.

The conclusion:

... but with an ideal compression ratio of 17:1 it does not look any better than before:

measured 25 -28 bar: very good

measured 20 -24 bar: OK, usable

measured 16 -19 bar: no longer good

measured 15 bar and less: bad - does not start at all or hardly at all when it gets cold