A

aaaleks

Guest

Hi everyone.

I am sorry, my english is not very well.

I have zetor 8111. Now i have problem.

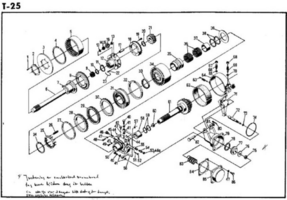

WHile i am driving it, it change from hi to lo speed itself.When it is on lo speed, zetor do not want to change to hi speed. Olso when i use the pto, it is stopping under pressure, or when i load it. Is the problem in the pump, which is in the gears. I will look the pto pack.how can i test the amplifier.Is there anything to change in it, as seals or o rings??? If it is not the pump, what i have to change in that amplifier.Is it possible , the problem to be just in the amplifier or just in the pto pack and because of it the other think not to work???? Can anyone send me pictures????

Thanks to everybody for opinion.

I am sorry, my english is not very well.

I have zetor 8111. Now i have problem.

WHile i am driving it, it change from hi to lo speed itself.When it is on lo speed, zetor do not want to change to hi speed. Olso when i use the pto, it is stopping under pressure, or when i load it. Is the problem in the pump, which is in the gears. I will look the pto pack.how can i test the amplifier.Is there anything to change in it, as seals or o rings??? If it is not the pump, what i have to change in that amplifier.Is it possible , the problem to be just in the amplifier or just in the pto pack and because of it the other think not to work???? Can anyone send me pictures????

Thanks to everybody for opinion.