Clutch not working on 1992, 5245

I have read many of the posts on stuck clutches and they were very helpful. However, I don't think i saw one where the clutch pedal (eventually) got stuck in the up position. I'm going out to try some of the things i read about but in the mean time i figured i would post incase a stuck clutch and a stuck clutch pedal were good diagnostic symptoms.

So, the tractor sat outside for a while, clutch would not disengage with pedal down. Got it out of gear, started it and drove up a hill with the pedal pressed in and it let go; great! Then, sat for a long time outside and again, the clutch would not disengage when I pushed the pedal down when trying to start it. Got it out of gear, fired right up, slammed it back into gear with loader bucket driven into the ground, wheels started turning with pedal pushed down but the wheels just started digging down and the clutch would not let lose. But wait, it gets better! I decided to brace the clutch pedal in the depressed position in the hopes that in a few days, it might just let go in the middle of the night. So, a week or two later I went to check if it worked, it did not, and now, after letting the clutch pedal up, it will not go back down. I can stand on the pedal, and it won’t move a millimeter (not going to start jumping on it, I have enough problems already).

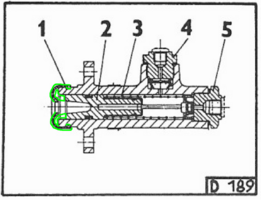

There’s plenty of hydraulic fluid, replaced the slave several years back, master is not leaking. It’s not technically difficult to split these things but it is a pain and I’d rather not do it until I know there are no other choices.

Any help and ideas would be most appreciated!

I have read many of the posts on stuck clutches and they were very helpful. However, I don't think i saw one where the clutch pedal (eventually) got stuck in the up position. I'm going out to try some of the things i read about but in the mean time i figured i would post incase a stuck clutch and a stuck clutch pedal were good diagnostic symptoms.

So, the tractor sat outside for a while, clutch would not disengage with pedal down. Got it out of gear, started it and drove up a hill with the pedal pressed in and it let go; great! Then, sat for a long time outside and again, the clutch would not disengage when I pushed the pedal down when trying to start it. Got it out of gear, fired right up, slammed it back into gear with loader bucket driven into the ground, wheels started turning with pedal pushed down but the wheels just started digging down and the clutch would not let lose. But wait, it gets better! I decided to brace the clutch pedal in the depressed position in the hopes that in a few days, it might just let go in the middle of the night. So, a week or two later I went to check if it worked, it did not, and now, after letting the clutch pedal up, it will not go back down. I can stand on the pedal, and it won’t move a millimeter (not going to start jumping on it, I have enough problems already).

There’s plenty of hydraulic fluid, replaced the slave several years back, master is not leaking. It’s not technically difficult to split these things but it is a pain and I’d rather not do it until I know there are no other choices.

Any help and ideas would be most appreciated!