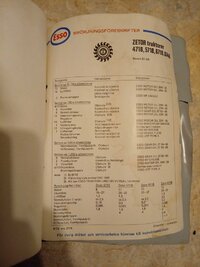

Hello, I recently bought my first own tractor a Zetor 5718 which I am going to repaint and fix. From the 4 hour drive home I find it to be a lovely tractor, nice that it has a suspended front axle too. Going to be used for getting rid of snow and some lighter work like a hay rake and a tedder. I thought I'd register on a forum if I needed to ask any questions, and I already have some

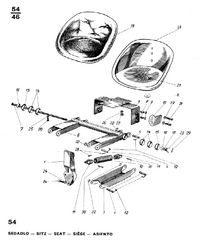

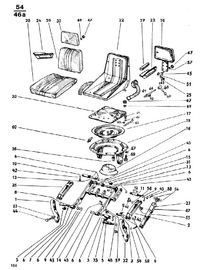

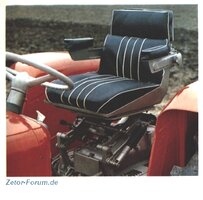

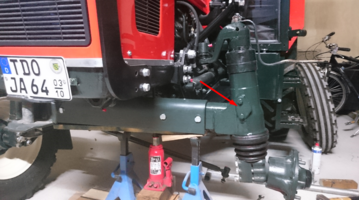

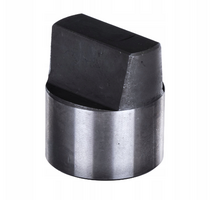

I've downloaded some spare parts catalogs of the internet and I can't really seem to find the right seat, I kind of wanted to have the original seats and not buy a different one but the old seat is not really in great shape. Also from the instruction book it says there should be bolts to lock the front axle suspension for doing work with a front loader, what do these look like? Are they just normal bolts? I can't seem to find any in the toolbox so I assume they are gone.

I've downloaded some spare parts catalogs of the internet and I can't really seem to find the right seat, I kind of wanted to have the original seats and not buy a different one but the old seat is not really in great shape. Also from the instruction book it says there should be bolts to lock the front axle suspension for doing work with a front loader, what do these look like? Are they just normal bolts? I can't seem to find any in the toolbox so I assume they are gone.