Zetor engines meet strict emission standards

Brno, December 8th 2014: ZETOR TRACTORS a.s., which manufactures the most compression ignition engines in the Czech Republic, has developed Zetor engines that meet the very strict STAGE IV emission limits, which is important with respect to the applicable regulations of the European Union. Another item of news in the field of engines is that cooperation has been established between ZETOR TRACTORS a.s. and the German company DEUTZ AG, which is among the global leaders in engine manufacturing.

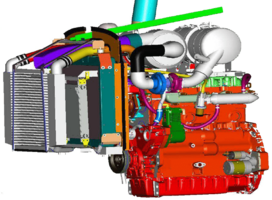

Thanks to the long-term development of combustion and optimisation of the cylinder unit, Zetor brand engines achieve low fuel consumption and low emission values. The fulfilment of the relevant emission standards is the future of Zetor engine development, says David Kollhammer, Director of the Technical Section for ZETOR TRACTORS a.s. In 2014, new Stage IV emission standard started to be effective for tractor engines of power within the range of 75-173 HP which make approximately two thirds of Zetor production. Stage IV standard is specific in very strict limits regarding nitrogen oxides (NOx) allowing the amount of 0.4 g/kWh. To meet this, we employ the technology of active DPF filter (diesel particulate filter) and SRC (selective catalytic reduction), David Kollhammer explains.

The objective of extensive development and testing of Zetor engines is not only to meet legislative requirements, but above all to ensure the continuously improved features of these engines in favour of the customer. The benefits of Zetor brand engines include low consumption, simplicity and easy maintenance.

Cooperation with the best

The existing offer of Zetor engines will be expanded both by engines from DEUTZ AG, which ZETOR TRACTORS a.s. will be cooperating with. Engines from the German manufacturer will be added to the ZETOR brand engines, used primarily in the new model series of tractors that ZETOR TRACTORS a.s. plans to introduce in 2015 and 2016. DEUTZ AG engines will be used both in lower and higher performance categories.

Cooperation with DEUTZ AG allows us to fully concentrate on the development of new tractor models as a whole. Thanks to our own production and development centre in Brno-Leň, which all manufactured Zetor brand tractors go through, we can guarantee the quality of our tractors, which is of foremost importance to us, explains David Kollhammer, Director of the Technical Section for ZETOR TRACTORS a.s.

By establishing cooperation with DEUTZ AG, ZETOR TRACTORS a.s. will endeavour to strengthen its position on the international market and improve customer satisfaction.

DEUTZ engines offer a modern concept with the Common Rail injection system. They are equipped with the DVERT (DEUTZ Variable Emission Reduction Technology) emission system. Using a CAN BUS, electronically controlled injection allows the engine to communicate with other tractor components (gearbox, dashboard, hydraulics), thereby contributing the better user comfort (automated transmission, dashboard display, etc.). The compact constructed engines apply the most advanced construction and technological trends. The benefits for users include both low noise and a maintenance-free solution with a long lifetime. The main benefits of DEUTZ engines with performance exceeding Zetors existing offer include excellent performance parameters, for instance the sharp rise in torque particularly at lower rotations. Fuel consumption is also favourable.

So what Mr. Kolhammer is explaining is that they continue to build Zetor 4 cylinder engines, yet install an SCR system and an active soot filter, to achieve TIER 4 Final emissions.

Clearly, because of the parallel introduction of their own TIER 4 Final 4 cylinder engine, this means that this cooperation with Deutz does NOT mean the end of the Zetor 4 cylinder engine, unlike some newspapers write. (!?!)

And the Deutz press release:

DEUTZ to enter into new partnership with Zetor

DEUTZ to embark on long-term cooperation with ZETOR TRACTORS a.s. Czech producer of agricultural machinery to equip its tractors with TCD 2.9 L4 and TCD 6.1 L6

In Czech agricultural machinery producer ZETOR TRACTORS, Cologne-based DEUTZ AG was able to secure another partner for long-term cooperation in the agricultural equipment sector.

The focus of the Brno-based corporation is on manufacture of tractors and attachment systems such as a front-end loader. ZETOR produces tractors in the performance range from 60 to 150 HP at its plant in Czech Republic. They are primarily destined for the European market but also are sold in North America as well. In the future, new model series of tractors that ZETOR TRACTORS a.s. plans to introduce in 2015 and 2016, will be equipped with DEUTZ engines of the TCD 2.9 L4 and TCD 6.1 L6 model series.

"We are pleased to have gained a new partner in ZETOR that is based in Central Europe. Our partnership with the Czech tractor manufacturer ZETOR will reinforce our presence in the European market. This new OEM will further broaden the base of our business model in agricultural equipment", so Michael Wellenzohn, DEUTZ AG Board of Management, Sales/Service and Marketing.

So what Deutz is saying is that they are going to sell TCD 2.9 and TCD 6.1 engines to Zetor, to be implemented into production during 2015/16.

According to what factory spokesmen have said informally to forum user Forterra11441, it involves the new Major (which means it will get the TCD 2.9) and new six cylinder ranges which will get the TCD 6.1

In spite of all, i take my hat off for Zetor R&D for what they have done in the past few years, competing against competitiors nearly 10 times as big..

Last edited by a moderator: