- Joined

- Sep 9, 2012

- Messages

- 874

- Location

- Wiedemar, Germany

- First name

- Joachim

Machinery:

Zetor 2011, Zetor 3045, Zetor 5011, Zetor 7340 Economic

If this little guide was helpful to you, please rate it here, just to the right. Thanks. :like

Tip: Tire conversion table, comparison table

Regardless of whether diagonal or radial tires - it's mostly just about these size details:

Nominal width (also called "cross-sectional width")

The width of the tire in mm (millimeters) or " (inches), measured from sidewall to sidewall with the tire unloaded, mounted on the recommended rim and inflated to tire operating pressure.

Section heightThe height of the tire sidewall, stated in % of the nominal width or in millimeters or inches.

Rim diameterDiameter measured from bead seat to bead seat.

Static radiusDistance from wheel center to ground at nominal load and air pressure conditions. Usually stated in mm.

Outer diameterMaximum diameter of an unloaded tire mounted on the recommended rim and inflated with operating air pressure in mm.

Inch / millimeter conversion: 1" inch corresponds to 25.4 mm

Size and profile designations

Bias-ply tires

Tire size: 16.9/14 - 28

- "16.9" is the nominal width in inches

- "/14" is the section height in inches

If this value is missing from a tire size, it is a so-called balloon tire with nominal width = cross-section height!

- " - " as identification of a diagonal tire

- "28" indicates the rim diameter in inches

Tire size: 11 - 28 (balloon tires)

- "11" is the nominal width and cross-section height in inches

The actually necessary "/11" was often omitted in balloon tires in the past.

- " - " as identification of a diagonal tire

- "28" is the rim diameter in inches

Radial tires

Tire size: 16.9/14 R 28

- "16.9" is the nominal width in inches

- "/14" is the section height in inches

- "R" as a designation for a radial tire

- "28" is again the rim diameter in inches

Tire size: 320/75 R 32

- "320" is the nominal width in millimeters

- "/75" indicates the cross-sectional height in % in relation to the nominal width

- “R” as the designation of a radial tire

- "32" is the rim diameter, also here still in inches!

Load capacity and speed index

There is also information on the side of the tire about its load capacity and speed index as well as whether it can be driven with or without an inner tube.

TL = "Tubeless" (without tube)

TT = "Tubetype" (with tube)

The load index (also called load index) is indicated by a number code. See also: Tire code - Wikipedia - https://en.wikipedia.org/wiki/Tire_code#Load_index

The speed index is given as a letter or letter/number combination following the load index number code and indicates the maximum permissible speed that can be driven with the tire.

Mainly interesting for agricultural tires:

A1 up to 5 km/h

A2 up to 10 km/h

A3 up to 15 km/h

A4 up to 20 km/h

A5 up to 25 km/h

A6 up to 30 km/h

A7 up to 35 km/h

A8 up to 40 km/h

B up to 50 km/h

C up to 60 km/h

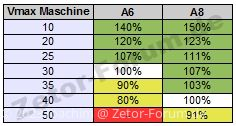

Assignment of load <> speed

This means that a tire with the speed rating A8, i.e. up to 40 km/h Vmax, for example, can be loaded with up to 107% of the specified load capacity (see load index) at 30 km/h. At 10 km/h even up to 150% of the maximum load for A8 specified in the tire tables.

Example: "A8 120"

According to the load index, a tire with a number code of "120" has a load capacity of 1400kg. According to the table, “A8” tells us that the tire can carry this load at up to 40 km/h. So we can now easily calculate the maximum loads at reduced final speed:

- 1400 kg load capacity at 40 km/h per wheel/tire

- 1498 kg load capacity at reduced 30 km/h per wheel/tire

- 2100 kg load capacity at reduced 10 km/h per wheel/tire

Some manufacturers specify special values for front loader work, which involve an increase in tire air pressure, but this means that significantly higher loads are possible. If in doubt, always contact the tire manufacturer or tire seller and, if necessary, have it confirmed in writing.

You can find the complete tire speed index here: Geschwindigkeitsindex – Wikipedia - http://de.wikipedia.org/wiki/Geschwindigkeitsindex

Advantages and disadvantages of diagonal <> radial technology

Bias-ply tires

With conventional diagonal tires, the tread and tire sidewall form a unit, which is why every movement in the sidewall is passed on to the tread, which in turn leads to a high level of movement of the tire.

+ cheap to purchase

+ less susceptible to puncture injuries (due to design)

- Slip on the ground (high self-motion)

- uneven pressure distribution of the contact area

-, among other things, resulting in higher wear

- and lower tractive force transmission

- lower spring properties (comfort)

- higher fuel consumption

Radial tires

The radial technology enables the tread and tire sidewall to work independently, meaning that the movements of the sidewall are not transferred to the tire tread. The uncontrolled movement of the tire, i.e. the slip, is significantly reduced.

+ reduced slip on the ground

+ even load distribution in the contact area

+ thereby, among other things, better tractive force transmission

+ and lower wear

+ driving with low air pressures possible

+ more suspension (comfort)

- higher purchase price

Re-tiring

Now you might think that a tire size 16.9/14 - 28 (i.e. diagonal) in a radial version would correspond to size 16.9/14 R28.

But it's not quite that simple.

The nominal width of the radial tire is rounded down in millimeters:

e.g.: 16.9" x 25.4 mm = 429.26 mm ~ 420mm

You might think it's not worth mentioning, but you should know it. Sources:

Bohnenkamp - Technical Tire Guide 2014/2015