I see that meanwhile

Zetor gives 6500kg rear axle rating on the Crystal: I think it is an 85mm axle, where Deere allows 7000kg on an 86mm so they might still be a bit conservative in their rating.

Anyways, 6500kg is fine for the HSX 140. 150hp and up, needs a bigger axle.

I also don't like to see Zetor install a Deutz. But realistically, you also have to keep an eye on the service network. We have a workforce (shortage of skilled workers) in Germany and fewer and fewer people want to get their hands dirty while working. As a result, further training costs time and money.

If I install brands that are well-known on the market, you have more synergy effects for the workshops and it gives dealers and workshops the opportunity to reduce costs.

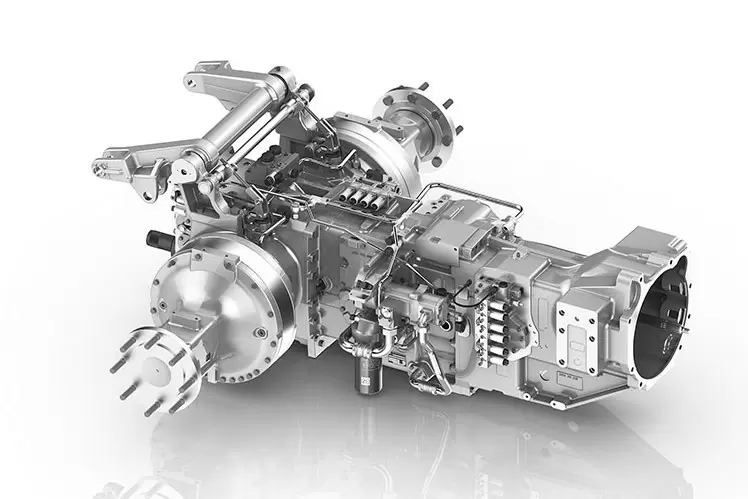

My brother in laws younger brother worked for a Case dealership: When there was a problem with a Case CVX (in the time before New Holland made their own and the ZF-Steyr CVX was still a fairly new tractor) a ZF specialist came to assist in the repair. Even large dealers didnt have the specific knowledge untill they learned the tricks from ZF service technicians and they had CVX gearboxes opened more often.

So, the argument that ZF is more familiar is not really valid when dealers call in the local ZF service point. In wheel loader transmissions, ZF Netherlands could rebuild transmissions, they would change every single part because they werent really sure about themself. But we could do it much cheaper and even rebuilt ZF transmissions for JCB dealers because we only replaced what was broken, or worn more than 25% (which was usually just two or three parts) which would make it run for another 10 to 20.000hrs.

Zetor importers need those specialists too, to assist dealers. Not just the garden dealerships they are left with, but also the professional dealerships that they have lost in the past 20 years. One of Zetors largest dealers in Holland was also hired by other dealers to repair transmissions. They even repaired a 10540 transmission shipped to and from Holland, from a Canadian customer because local dealers were clueless ! This dealer is now no longer Zetor.

Maybe Zetor needs a remanufacturing scheme like John Deere or Fendt. Send the box to Czechia for rebuild. As in the wheel loader transmission example, companies that do it once a month can do it way faster and efficient than a shop who isnt sure of what they are doing and therefor replaces every part as a precaution.

How many dealers only make Zetor?

Most will have at least a second brand in their range.

Here ? All of them. Those who had Zetor as a second brand, let go when all the major manufacturers started to build economy tractors.

Those who had Zetor as a first brand (and sold a new tractor every week in the 80s), well Zetor has left them on their own, so they also gave in to the pressure of the larger brand who wants exclusivity from their dealers. Zetor was not worth risking to loose their other dealership over, when Zetor only has a basic product offering up to 140hp.

Nonetheless, the Crystal Agropoland 260 was as expensive as a Magnum MX270, and 20.000 Euro cheaper than a Deutz Agrotron 260 with the same components. Therefor it was unable to compete in the market.

Therefor i am afraid that a Zetor with only German components will have the same problem... When compared to a Deutz Fahr, the customer gladly pays 20.000 euro more for the better resale value and better dealer of Deutz, or the better resale value and better service from the Magnum for the same price.

I am afraid that ZF takes the profit while Zetor makes the struggle...

Zetor has no machining centers to machine six pot blocks, that line was set up in ZTS Martin in the 70s. So going for Deutz engines and stopping engine development entirely, i get that. But i am afraid that with a component tractor, all profit goes to ZF (they know damn well that they are the only independent OEM supplier in the market) while Zetor has a foundry and a machining hall for rear ends, with way more capacity than the 3000 tractors they build nowadays. The bottom line for the Zetor production facility will degrade too, the more they buy from elsewhere. In order to make Proxima and Forterra production more profitable, they need more turnover, buy steel ingots for the foundry in larger batches for less money, operate the machining centers in two or three shifts instead of just the day shift, just create economy of scale.

They could also cooperate with ZF on transmissions, like Fendt did with the Favorit 500 series: They bought powershuttle and powershift modules and electronic control units from ZF, and produced the gears, castings and rear axles themself.

Even just license building the rear ends in Brno is an option, create critical mass for the purchase department, so that their own production (Proxima, Forterra) becomes more profitable.

If they really want to be cool they co-develop with ZF, and ZF starts to sell their own version to OEM customers after a year so Zetor has the premiere. Although i believe ZF created this 6F/3R powershift in order to get people to buy a CVT instead, they cant match Deeres DirectDrive or Case Octoshift. A 30 speed close ratio Zetor DSG would instead diminish demand for a CVT option, so i dont know if ZF is even interested in a DSG that eats into CVT sales...

What i envision is 5 DSG gears with a two speed powershift in front, for instant gear change when the load changes suddenly: Where Deeres DirectDrive stalls when you take a run before climbing the silo with a heavy trailer and the engine lugs down when it starts to climb the heap because the computer expects acceleration and preselected the next higher gear, this variant would first shift down the powershift which signals the DSG to immediately preselect the next lower DSG gear, giving way more time to predict and preselect a next DSG gear.

This would have 60kmh top speed (or 50 at reduced engine speed) and gear spacing of 1.156 like the Forterra powershift, so with 10 speeds you get 15.5 to 60kmh speeds in high range. Then we start middle range at 21kmh, overlapping 3 speeds with high range. 10 speeds down covers 5.7 to 21kmh, covering all cultivating, ploughing mowing and baling, and most important: Allowing you to take off with a heavy silage trailer on a hill with all four wheels spinning without the engine stalling, like the Forterra does.. (you dont want to pull out into the road from the field in low range, then change ranges at standstill in the middle of traffic. Or drive all the way to the road in low range because middle range starts too high to take off in, in a muddy field, which was a problem with MF's original Dynashift) Then in low range we start with 7.5kmh, again 3 speeds overlap with middle range, giving speeds from 2 to 7.5kmh for all PTO driven harrows.

When the customer wants super crawl gears for deep spading machines and other specialty jobs, offer a crawl group with speeds of 2.7 to .7kmh.

In my lifetime i have never used a lower gear than low range 3rd on a UR1 with a 3 meter rotary harrow, which is about 2.3kmh with 60hp on a 3 meter harrow... I went so slow because i had no more power, (1000rpm rotavator driven at 540rpm) and at this point, there was no difference in power consumption between 1st, 2nd or 3rd gear low range so i worked in 3rd. So 2kmh is slow enough for 99% of all agricultural uses, and civil contractors who want slower, e.g. with forest choppers, would want CVT and dont buy Zetor either, Zetor doesnt have to invest in this niche. So 3 ranges from 2 to 60kmh with 3 speeds overlap between ranges suits the bill for 99.9% of customers.

If a crawl gear is fitted, one can also create the field range from 3 to 11kmh which allows for decent headland speed when turning on the headland whilst power harrowing. Then the crawl range would stretch from 1 to 4kmh..